JBA Upper Control Arms are assembled and ready to bolt into your Ford! American-made steel tubing, red powder-coat finish, replaceable ball joints, 2 grease ports for the JBA EZ lube bushings, and 1 grease port for the ball joint.

*UCAs are not symmetrical.

Fitment

Ford F-150 2021 to the current model year

Recommended

Wheel: 17" x 8.5" 4.75" backspace

Tire: 285/70R17 = 32.7" x 11.2"

The JBA Upper Control Arms for the 2021 Ford F150 is an essential upgrade for any driver seeking to maximize the performance and durability of their lifted truck. While sufficient for non-lifted use, the OEM control arms may not provide the geometry needed for more demanding conditions when the truck is lifted or leveled. This is where JBA's engineering expertise shines through, offering a superior alternative that is meticulously designed and manufactured for enhanced performance and longevity.

Crafted from 1026 DOM (Drawn Over Mandrel) steel, these control arms are significantly stronger and more durable than their OEM counterparts. The DOM process ensures a uniform grain structure within the metal, reducing potential weak points and improving overall strength. This is further augmented by CNC mandrel bent tubing, a precise manufacturing process that maintains a consistent diameter throughout the tube bends, ensuring optimal strength and integrity.

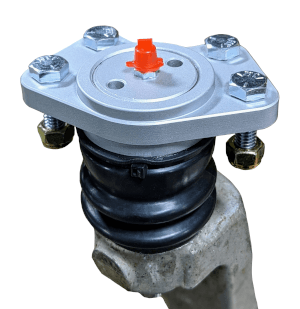

The bushing housing and sleeves are also CNC machined, guaranteeing exact fitment, and minimizing any potential issues with installation or alignment. This engineering expertise extends to the patented grease port in the bushings, allowing the grease to flow to the flange of the bushing and eliminating squeaking. These are serviceable and greaseable, providing ease of maintenance and increasing the product lifespan. Regular greasing helps to reduce friction and wear, extending the life of the bushing and enhancing the smoothness of your ride.

Built-in caster correction is another key feature of the JBA Upper Control Arms. This design element improves the vehicle's handling, particularly when driving at higher speeds. Correcting the angle of the steering knuckle, it helps give back the caster lost when the lift kit was installed.

The JBA Red powder coat finish is not just about aesthetics – it provides high durability and resistance to corrosion and chipping. This means your control arms will continue to look great and perform well, even in harsh environmental conditions.

In conclusion, the JBA Upper Control Arms offer a host of benefits for the discerning F150 owner. They enhance off-roading capabilities, improve road handling, and provide a smoother ride. Coupled with a lifetime warranty, it's clear that this product represents a commitment to quality and customer satisfaction.

The JBA Value Pack

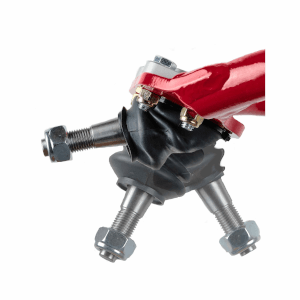

- JBA Max 90 Ball Joints™

- Patented JBA EZ Lube Bushings™

- JBA Lifetime Warranty

- JBA 365-day Return Policy

- JBA Installation Book

- JBA Stickers

Note: Using ball joint spacers voids the JBA Money Back and Replacement Warranty.

Ball Joint Construction

Ball Joint Construction

90°Range of Motion

90°Range of Motion

JBA EZ Lube Bushings

JBA EZ Lube Bushings