JBA Upper Control Arms fits

- 2005-2015 NISSAN XTERRA

- 2005-2021 NISSAN FRONTIER

- 2005-2012 PATHFINDER

The JBA Value Pack

- JBA Max 90 Ball Joints™

- Patented JBA EZ Lube Bushings™

- JBA Lifetime Warranty

- JBA 360-day Return Policy

- JBA Installation Book

- JBA Stickers

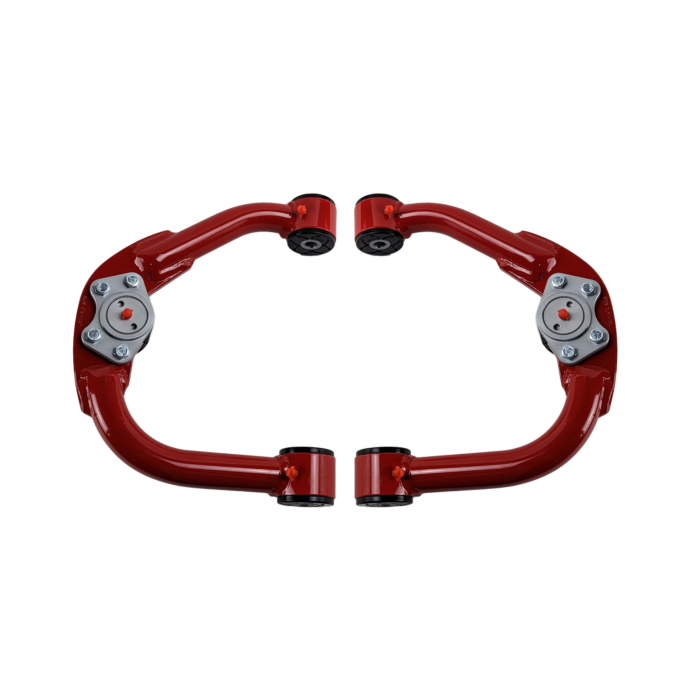

Features That Set JBA Apart:

- US-Made Steel Tubing: The heart of JBA's upper control arms is the robust 1026 DOM A513-5 domestic tubing, boasting an imperious 1.313" OD x 1.00" ID. It's a significant upgrade that breathes ruggedness into your ride's skeleton.

- Vibrant Red Powder-Coat Finish: Not only does it catch eyes, but the finish also serves as the first line of defense against the elements—because off-roading involves a collision course with nature.

- Replaceable Ball Joints: Designed for longevity, the JBA Ball Joints outclass Uni-Balls with an unmatched 90-degree range of motion, letting you tackle any terrain with ease. Grease up the fitting with just a few pumps, and your control arms remain as nimble as ever.

- Innovative Bushings: The included JBA EZ Lube Bushings redefine durability. With the added convenience of grease ports and pressure relief valves, you needn’t fret about over-lubrication or bushing extrusion. They're built with advanced synthetic elastomer—a polymer known for its incredible tensile strength and elasticity perfect for both daily drives and demanding off-road excursions.

- Three Grease Ports: Maintenance is a breeze. Simply pump grease until it surfaces between the washers and the bushing—proof of well-lubricated control arms.

With an installation timeframe averaging between 1 to 3 hours, replacing your stock arms with the JBA edition is an investment in immediate improvement. Weighing in at a mere 20 lbs.